Tantalite Ore Processing Equipment Dry Magnetic Separator

Introduction of Three Disc Magnetic Separator

The device is a Dry Intensified Magnetic Separator, applicable for separations of ilmenite, rare earth ore, chromite, tungsten and tin ores, limonite, columbium and tantalum ores, zircon, rutile, monazite, andalusite, garnet, kyanite, feldspar, quartz and other minerals with magnetic differences or removal of iron in nonmetallic minerals.4 varieties of products can be obtained by separation of the device.

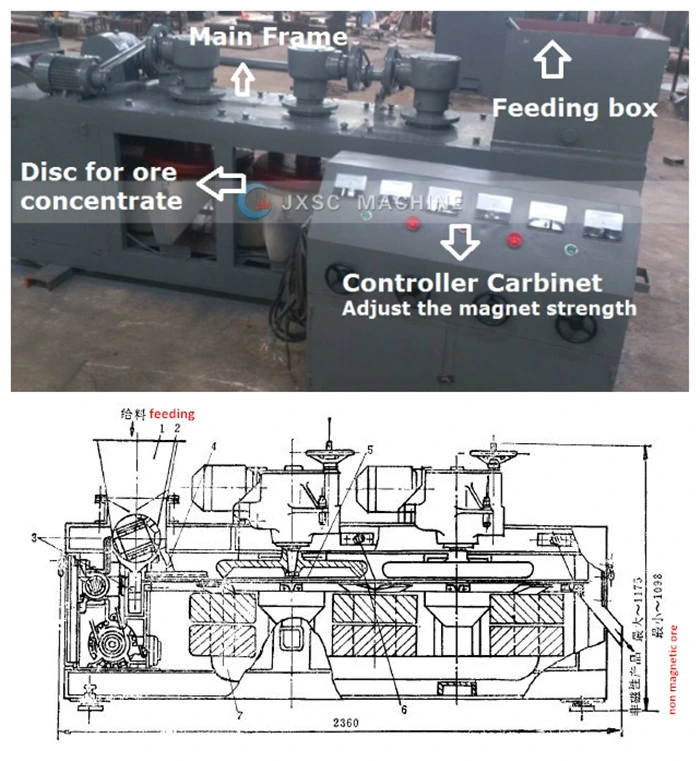

Main device comprises feeding unit, weak magnetic roller, drive part, material conveying apparatus, magnetic disk, electromagnetic system, frame and others. The electric control section consists of components of control, voltage regulation, rectification, instrument and so on. It features compact structure, stable performance, easy installation and convenient operation and maintenance.

Advantage of Three Disc Magnetic Separator:

1. This machine could separate four different usefull mineral in one time.

2. This machine could get the final concentrate of three to four mineral.

3. Ta & Nb grade could reach 60% by using this machine.

4. Easy to install, adjust, operate.

5. Magnetic intensity adjustable, could be used for other mineral concentration.

Structure for Three Disc Magnetic Separator

Factory&Certificates

Jiangxi Shicheng Mine Machinery Factory

is a leading mining machinery manufacturer with over 30 years experiences, providing complete set processing equipments for Gold ore, Tin ore, Tungsten ore, Iron ore, Diamond, Coltan ore, Silica sand, Zircon sand, Black sand, Chrome ore, ect. As well as complete set small lab mining machines are available.

Main products: trommel screen, trommel scrubber, shaking table, spiral chute separator, jig machine, centrifugal concentrator, sluice box, vibration screen, melting furnace, jaw crusher, hammer crusher, ball mill, flotation machine, spiral classifier, as well complete set small laboratory mining equipments.

Main market: Africa, South Amercia, Europe, Southeast Asia, Asia,ect. Our cooperated customers cover Mali, Ghana, Sudan, Uganda, Mozambique, Suriname, Zambia, Nigeria, Cameroon, Madagascan, Malasia, Indonesia, Korea, Philippines, Monglia, Singapore, Inida, Iran, Mexico, Brazil, Chile, Peru, Spain, Canada, Austrilia,U.S, UAE,ect.

Our Core Advantages as below :

1.+30 years history FACTORY at mining machinery

2.Provide engineer team after sales service

3.Provide Complete set mineral processing equipments

4.Provide Sample testing service in factory lab for free

5.Provide professional Mining Solution Consulting

6.Provide professional flowchart designing and drawing

7.Provide engineer door to door service for installation,commissioning,starting up and training.

Company certificates

Products Quality Certificates

Our services

Pre-Sales Service

*Inquiry and consulting support*Ore sample testing support

*View our Factory

*Design Flowchart

After-Sales Service

* Training how to instal the machine, training how to use the machine.* 1 year warranty

* Engineers available to service machinery overseas.

Our exhibitions:

Every year we go abroad to participate in exhibitions.So far the exhibitions we have attended have USA Las Vegas Fair,Peru Fair,Russian Fair,Mongolian Fair,Burma Fair,Indonesia Fair,Ghana Fair,South Africa Fair,Nigeria Abuja Fair.

JXSC mine processing equipments have gone into global countries through exhibitions.We have enjoyed a good reputation in the majority of users because of excellent quality,reliable performance and professional service.

More products display

FAQ

1.How is the quality of your products? (mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Contacts

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best EXW-Factory Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is your capacity per hour? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?