Rapid Mixing/ High speed shear/ pharmaceutical machine/ Pelletizer/ Extruder/Granulator for Pharmaceutical

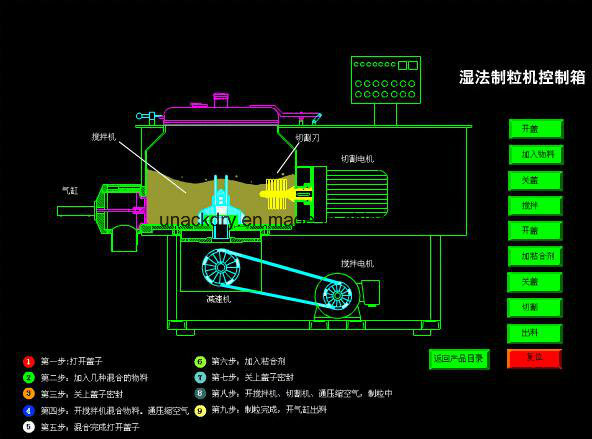

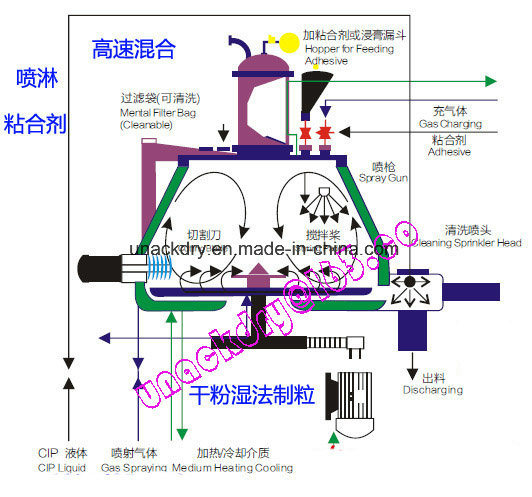

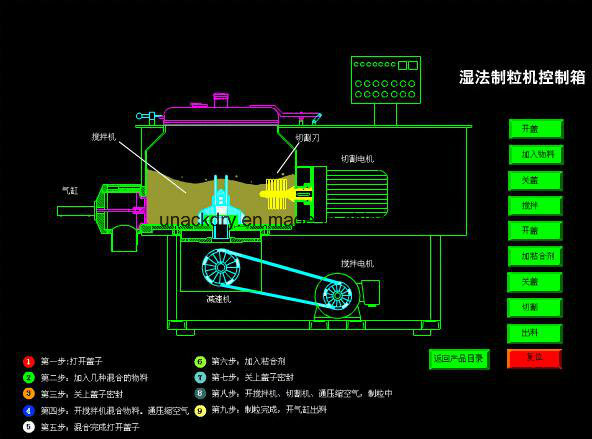

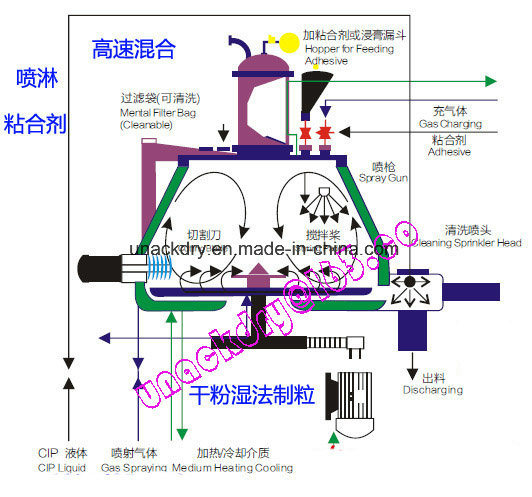

Working Principle

The powder raw material and adhesive in a cylinder are fully mixed at the bottom to become a humid soft material. Then it is cut by high-speed cutter and become uniform granules .

Characteristics

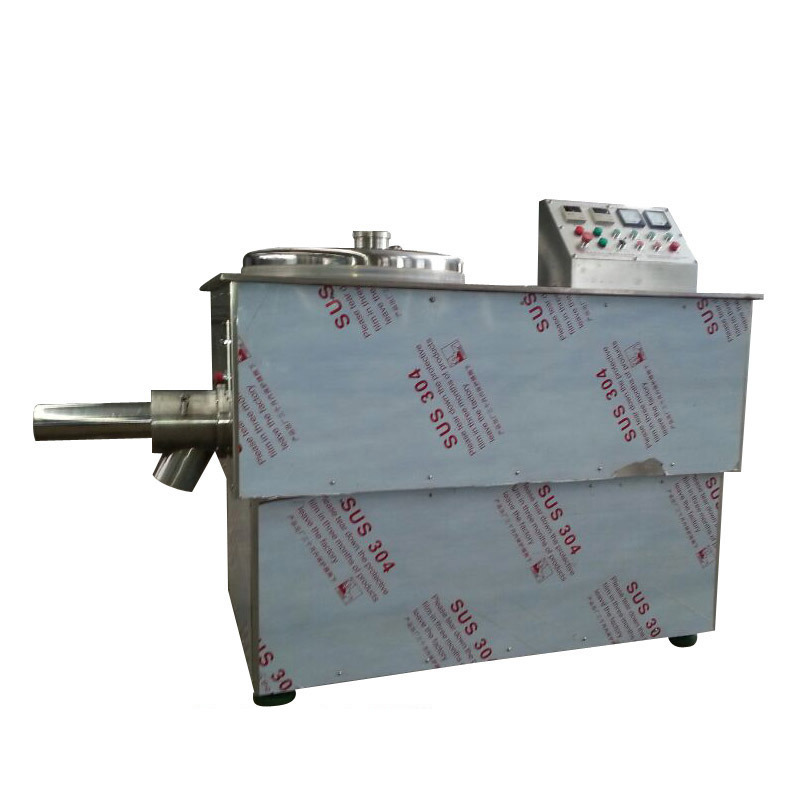

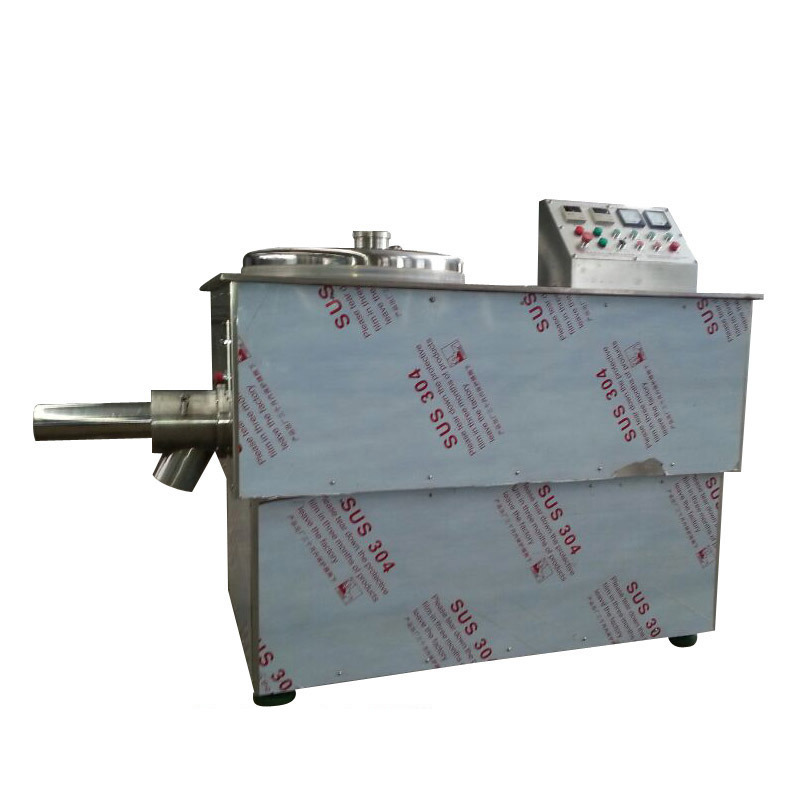

The machine adopts horizontal cylinder structure, its structure reasonable.

Air ¬lled seal shaft for to drive. When washing , it can be changed to water.

Fluidized Granulation, the granule is around ball shape. Its ow ability is good.

Compared to traditional process, 25% of adhesive can be reduced and the drying time is short.

The dry mixing time is 2 minutes and the granulating time is 1-4 minutes.

Compared to the traditional process , 4-5 times of ef ¬ciency is raised.

Dry mixing ,humid mixing and granulating are ¬nished in the same sealed container.

The whole operation has strict safe and protective measures.

Jacket type might be adopted on request.

Technical Parameter

Working Principle

The powder raw material and adhesive in a cylinder are fully mixed at the bottom to become a humid soft material. Then it is cut by high-speed cutter and become uniform granules .

Characteristics

The machine adopts horizontal cylinder structure, its structure reasonable.

Air ¬lled seal shaft for to drive. When washing , it can be changed to water.

Fluidized Granulation, the granule is around ball shape. Its ow ability is good.

Compared to traditional process, 25% of adhesive can be reduced and the drying time is short.

The dry mixing time is 2 minutes and the granulating time is 1-4 minutes.

Compared to the traditional process , 4-5 times of ef ¬ciency is raised.

Dry mixing ,humid mixing and granulating are ¬nished in the same sealed container.

The whole operation has strict safe and protective measures.

Jacket type might be adopted on request.

Technical Parameter

| Type | A | B | C×D | E | F |

| 50 | 320 | 950 | 1250×800 | 970 | 1650 |

| 150 | 420 | 1000 | 1350×800 | 1050 | 1750 |

| 200 | 500 | 1100 | 1650×940 | 1450 | 2050 |

| 250 | 500 | 1160 | 1650×940 | 1400 | 2260 |

| 300 | 550 | 1200 | 1700×1000 | 1400 | 2310 |

| 400 | 670 | 1300 | 1860×1100 | 1550 | 2410 |

| 600 | 750 | 1500 | 2000×1230 | 1750 | 2610 |

| Name | Type | ||||||

| 50 | 150 | 200 | 250 | 300 | 400 | 600 | |

| Volume L | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| output capacity kg/batch | 15 | 50 | 80 | 100 | 130 | 200 | 280 |

| admix speed r.p.m | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

| admix power kw | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 | 22/30 |

| cutting speed r.p.m | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 |

| cutting power kw | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

| compressed air consumption m3/min | 0.6 | 0.9 | 0.9 | 0.9 | 1.1 | 1.5 | 1.8 |

| weight kg | 500 | 800 | 1000 | 1300 | 1800 | 2200 | 2600 |