Standard air tightness test machine

Introduction:

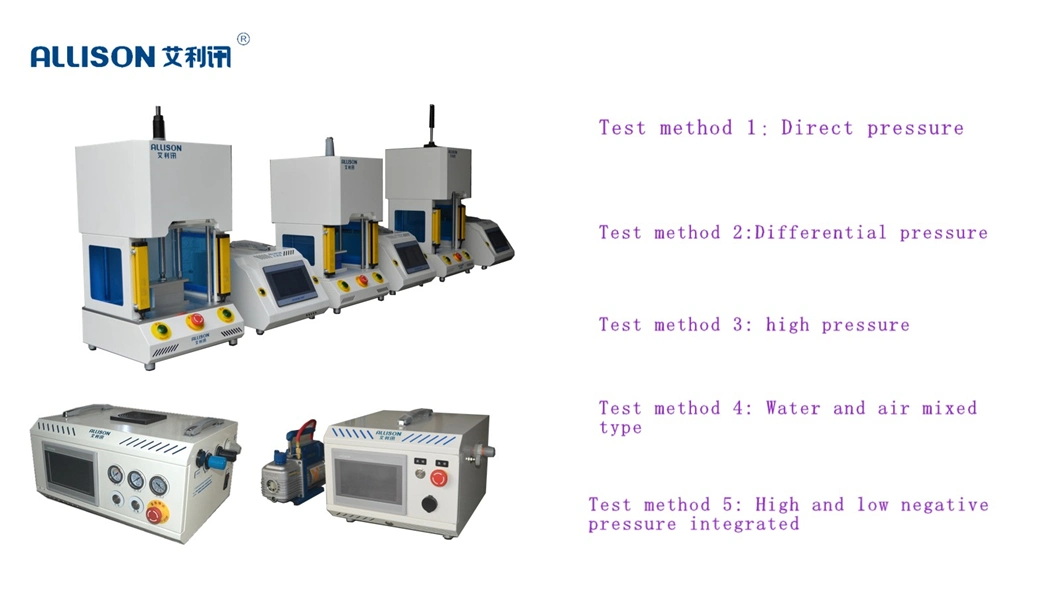

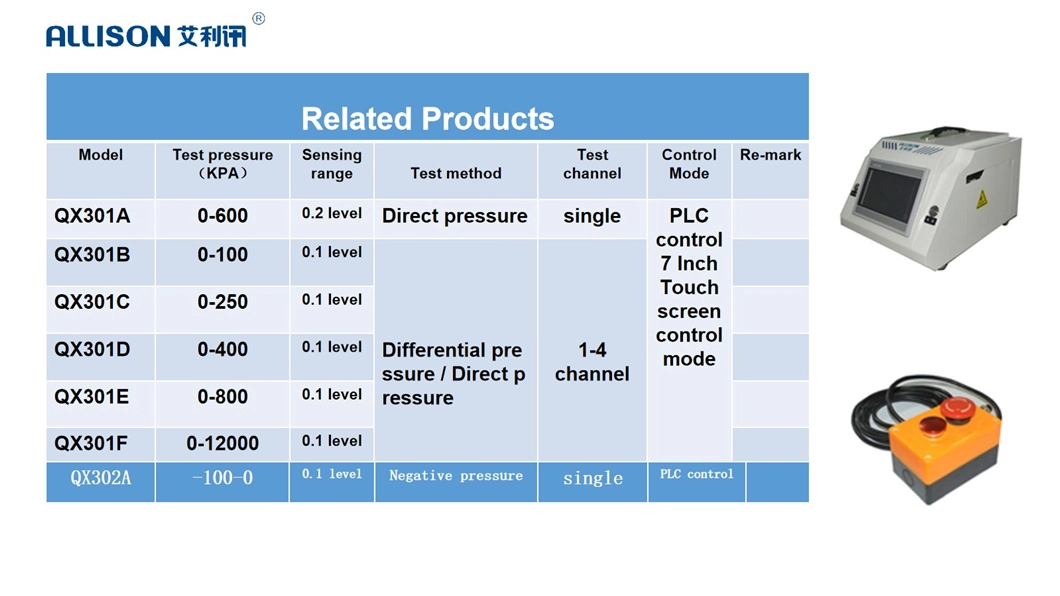

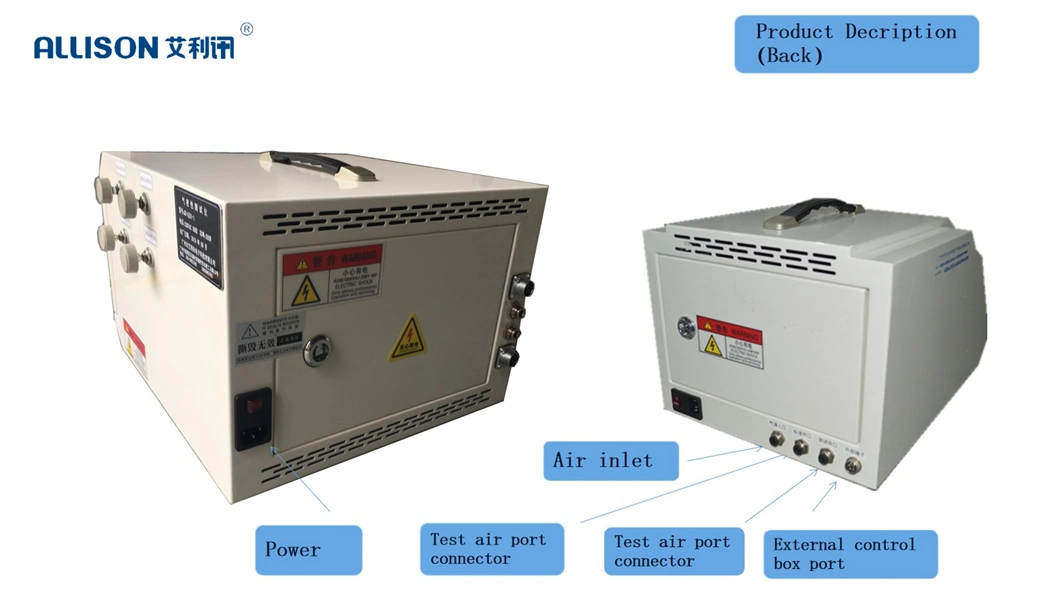

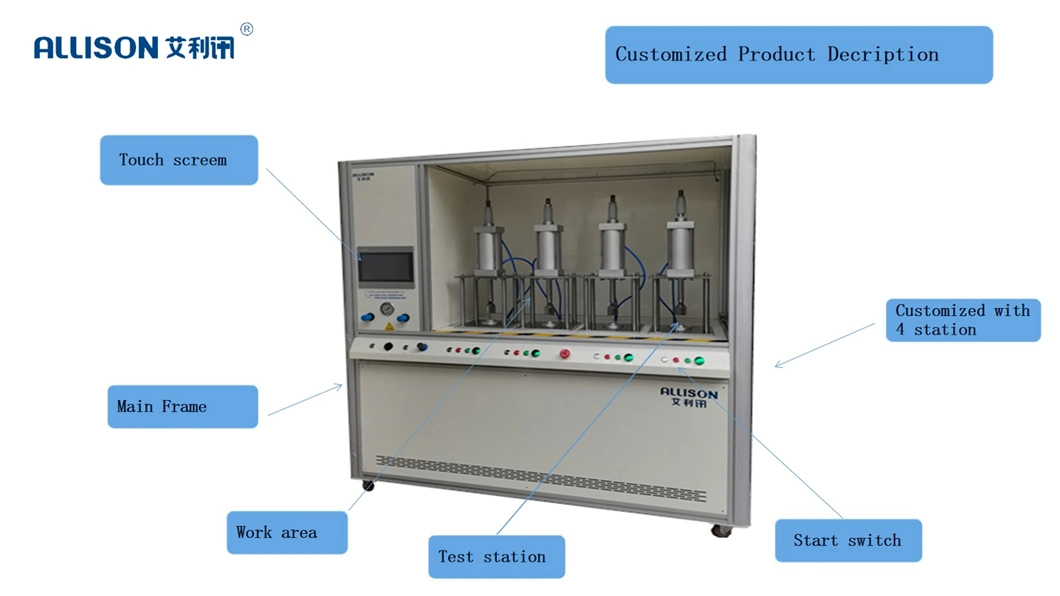

QX3001 series air tightness testing equipment is a combination of air tightness testing and automatic testing; it can be customized according to the requirements of root customers, and the internal testing module adopts the leak detector independently developed by the company. The test bench adopts PLC main control, touch screen Chinese display operation; adopts pneumatic principle to quickly clamp the product, wear-resistant silica gel as the sealing element, and detects the constant pressure and fluctuation of the internal pressure of the product through a high-precision pressure transmitter. Equipped with automatic judgment and alarm functions.OK-qualified, NG-unqualified and sound and light alarm;

The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable.

Scope of application: production line tightness testing, laboratory tightness testing and many other general industries. Non-standard customization can be made according to customer samples and related requirements.

Technical Characteristics:

1. Number of stations: single station

2. Pressure test range: 0.01-0.6Mpa, test pressure accuracy: 0.1 level/0.25 level/0.5 level

3. Holding time: 1s-99999S adjustable

4. Pressure method: 01: Direct pressure type 02: Differential pressure type 03: Vacuum type

5. Mechanical/Mitsubishi PLC control

6. Use single-phase power supply with ground wire: AC220V±10%, 50Hz 0.5KW

7. Equipment size: 300 X 420 X 250 Unit: MM

8. Beat: about 400 per hou

---------------------------------------------------------

Introduction:

QX3001 series air tightness testing equipment is a combination of air tightness testing and automatic testing; it can be customized according to the requirements of root customers, and the internal testing module adopts the leak detector independently developed by the company. The test bench adopts PLC main control, touch screen Chinese display operation; adopts pneumatic principle to quickly clamp the product, wear-resistant silica gel as the sealing element, and detects the constant pressure and fluctuation of the internal pressure of the product through a high-precision pressure transmitter. Equipped with automatic judgment and alarm functions.OK-qualified, NG-unqualified and sound and light alarm;

The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable.

Scope of application: production line tightness testing, laboratory tightness testing and many other general industries. Non-standard customization can be made according to customer samples and related requirements.

Technical Characteristics:

1. Number of stations: single station

2. Pressure test range: 0.01-0.6Mpa, test pressure accuracy: 0.1 level/0.25 level/0.5 level

3. Holding time: 1s-99999S adjustable

4. Pressure method: 01: Direct pressure type 02: Differential pressure type 03: Vacuum type

5. Mechanical/Mitsubishi PLC control

6. Use single-phase power supply with ground wire: AC220V±10%, 50Hz 0.5KW

7. Equipment size: 300 X 420 X 250 Unit: MM

8. Beat: about 400 per hou

---------------------------------------------------------

High pressure table air tightness test machine

Technical Characteristics:

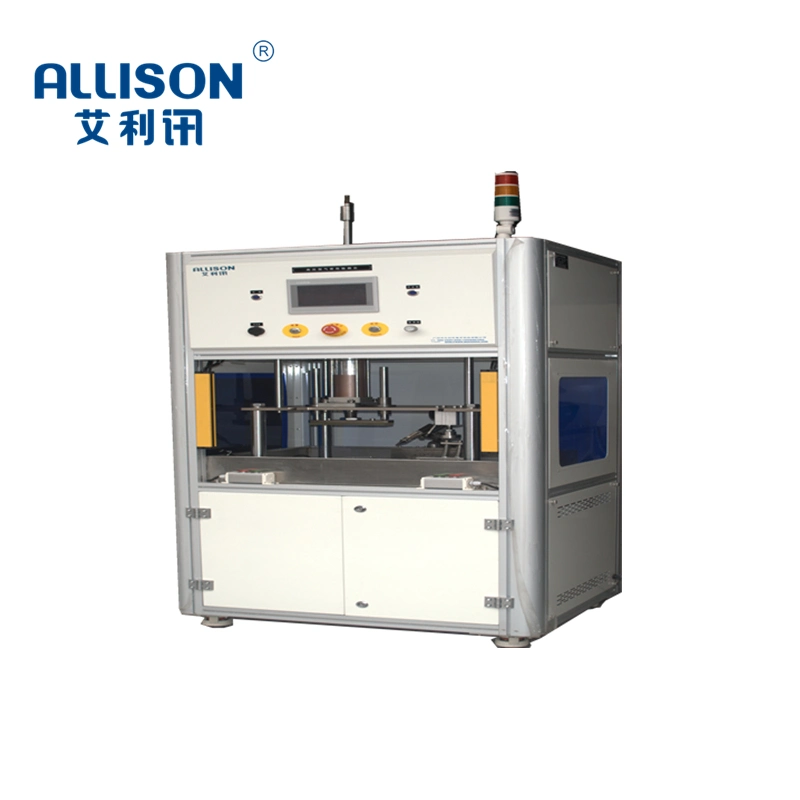

The high-pressure air-tightness testing equipment uses high-pressure air source as the main power source to test the high-pressure airtightness of the tested products; the test bench adopts PLC main control, touch screen Chinese display operation; adopts pneumatic principle to quickly clamp products, and is wear-resistant Silica gel is used as a sealing element, and a high-precision pressure transmitter is used to detect the difference in pressure inside the product and the upper and lower limits of the generated pressure to judge the tightness of the product. The fixture is a universal fixture that can reach more than 90% of diversified products according to the product design provided by the customer. The testing process is distributed, OK automatically enters the next step of testing, NG corresponding indicator light is on, and sound and light alarms; the accessories used in the testing equipment are imported and domestic well-known brands, and the work is stable and reliable.

Technical Characteristics:

1. Use single-phase power supply with ground wire: AC220V 0.5KW

2. Air source pressure: 0.1---1.6Mpa, test pressure accuracy: 0.1 level 0.25 level

3. Holding time: 1s--99999S adjustable

4. Applicable site of equipment: production line/laboratory

5. Operating environment humidity: 20%~90%RH

6. Places without severe shaking, impact, vibration, electromagnetic interference, dust, and corrosive air

7. Control method: mechanical/Mitsubishi PLC control

8. Equipment size: 350 X 400 X 280 MM

9. Beat: about 400 per hour

---------------------------------------------------------

Technical Characteristics:

The high-pressure air-tightness testing equipment uses high-pressure air source as the main power source to test the high-pressure airtightness of the tested products; the test bench adopts PLC main control, touch screen Chinese display operation; adopts pneumatic principle to quickly clamp products, and is wear-resistant Silica gel is used as a sealing element, and a high-precision pressure transmitter is used to detect the difference in pressure inside the product and the upper and lower limits of the generated pressure to judge the tightness of the product. The fixture is a universal fixture that can reach more than 90% of diversified products according to the product design provided by the customer. The testing process is distributed, OK automatically enters the next step of testing, NG corresponding indicator light is on, and sound and light alarms; the accessories used in the testing equipment are imported and domestic well-known brands, and the work is stable and reliable.

Technical Characteristics:

1. Use single-phase power supply with ground wire: AC220V 0.5KW

2. Air source pressure: 0.1---1.6Mpa, test pressure accuracy: 0.1 level 0.25 level

3. Holding time: 1s--99999S adjustable

4. Applicable site of equipment: production line/laboratory

5. Operating environment humidity: 20%~90%RH

6. Places without severe shaking, impact, vibration, electromagnetic interference, dust, and corrosive air

7. Control method: mechanical/Mitsubishi PLC control

8. Equipment size: 350 X 400 X 280 MM

9. Beat: about 400 per hour

---------------------------------------------------------

Water and gas mixture density test machine

Introduction:

The QX2Y series of air tightness and pressure tester is designed for high-precision, high-pressure auto parts for air tightness testing and pressure testing. Mainly check the sealing performance and pressure resistance of the product. Through PLC monitoring, tightness detection, water-gas mixed pressure resistance detection, pulse detection, pressure gradually increasing pressure and other detection modes. The relevant data in the test can be displayed by digital and curve. Data recording function and product data analysis ability. The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable. Scope of application: laboratory sealing test and product durability analysis. Non-standard customization can be made according to customer samples and related requirements.

Technical Characteristics:

1. Number of stations: double station

2. Pressure test range: 0.1-1.5Mpa, test pressure accuracy: ≤0.25 level/0.5 level

3. Holding time: 1s-99999S adjustable

4. Applicable site for equipment: laboratory testing/production line testing

5. Operating environment humidity: 20%-85%RH

6. Optional function: A: Data USB export B: Scanner function C: Cloud data upload

7. Control method: Japan Mitsubishi PLC

8. Pressure method: 01: High pressure type 02: Low pressure type 03 Pressure gradually increasing type 04 Pulse type

9. Use single-phase power supply with ground wire: AC220V 1.75KW

10. Equipment size: 1250 X 650 X 1650 Unit: mm

---------------------------------------------------------

Introduction:

The QX2Y series of air tightness and pressure tester is designed for high-precision, high-pressure auto parts for air tightness testing and pressure testing. Mainly check the sealing performance and pressure resistance of the product. Through PLC monitoring, tightness detection, water-gas mixed pressure resistance detection, pulse detection, pressure gradually increasing pressure and other detection modes. The relevant data in the test can be displayed by digital and curve. Data recording function and product data analysis ability. The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable. Scope of application: laboratory sealing test and product durability analysis. Non-standard customization can be made according to customer samples and related requirements.

Technical Characteristics:

1. Number of stations: double station

2. Pressure test range: 0.1-1.5Mpa, test pressure accuracy: ≤0.25 level/0.5 level

3. Holding time: 1s-99999S adjustable

4. Applicable site for equipment: laboratory testing/production line testing

5. Operating environment humidity: 20%-85%RH

6. Optional function: A: Data USB export B: Scanner function C: Cloud data upload

7. Control method: Japan Mitsubishi PLC

8. Pressure method: 01: High pressure type 02: Low pressure type 03 Pressure gradually increasing type 04 Pulse type

9. Use single-phase power supply with ground wire: AC220V 1.75KW

10. Equipment size: 1250 X 650 X 1650 Unit: mm

---------------------------------------------------------

Air tightness test machine(High pressure precision type)

Introduction:

The QX-1Y series air tightness and pressure tester is aimed at high-precision, high-pressure accessories, complete machines, for air tightness testing and pressure testing, mainly for product sealing and pressure testing. Through industrial computer control and monitoring, tightness detection, pressure resistance detection, pulse detection, pressure gradually increasing and other detection modes. The relevant data in the test can be displayed by digital and curve. With data recording function and product data analysis capabilities. The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable. Scope of application: laboratory sealing test and product durability analysis. Non-standard customization can be made according to customer samples and related requirements.

Technical Characteristics:

1. Number of stations: single station

2. Pressure test range: 0.1-1.5Mpa, test pressure accuracy: 0.1 level/0.25 level/0.5 level

3. Holding time: 1s-9999S adjustable

4. Applicable site of equipment: laboratory testing

5. Control mode: direct pressure, differential pressure,

6. Optional function: A: Data USB export B: Scanner function C: Cloud data upload

7. Control method: Japan Mitsubishi PLC/industrial computer control

8. Pressure method: 01: High pressure type 02: Low pressure type 03 Pressure gradually increasing type 04 Pulse type

9. Use single-phase power supply with ground wire: AC220V±10%, 50Hz 1.75KW

10. Equipment size: 750 X 600 X 1650 Unit: MM

---------------------------------------------------------

Introduction:

The QX-1Y series air tightness and pressure tester is aimed at high-precision, high-pressure accessories, complete machines, for air tightness testing and pressure testing, mainly for product sealing and pressure testing. Through industrial computer control and monitoring, tightness detection, pressure resistance detection, pulse detection, pressure gradually increasing and other detection modes. The relevant data in the test can be displayed by digital and curve. With data recording function and product data analysis capabilities. The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable. Scope of application: laboratory sealing test and product durability analysis. Non-standard customization can be made according to customer samples and related requirements.

Technical Characteristics:

1. Number of stations: single station

2. Pressure test range: 0.1-1.5Mpa, test pressure accuracy: 0.1 level/0.25 level/0.5 level

3. Holding time: 1s-9999S adjustable

4. Applicable site of equipment: laboratory testing

5. Control mode: direct pressure, differential pressure,

6. Optional function: A: Data USB export B: Scanner function C: Cloud data upload

7. Control method: Japan Mitsubishi PLC/industrial computer control

8. Pressure method: 01: High pressure type 02: Low pressure type 03 Pressure gradually increasing type 04 Pulse type

9. Use single-phase power supply with ground wire: AC220V±10%, 50Hz 1.75KW

10. Equipment size: 750 X 600 X 1650 Unit: MM

---------------------------------------------------------

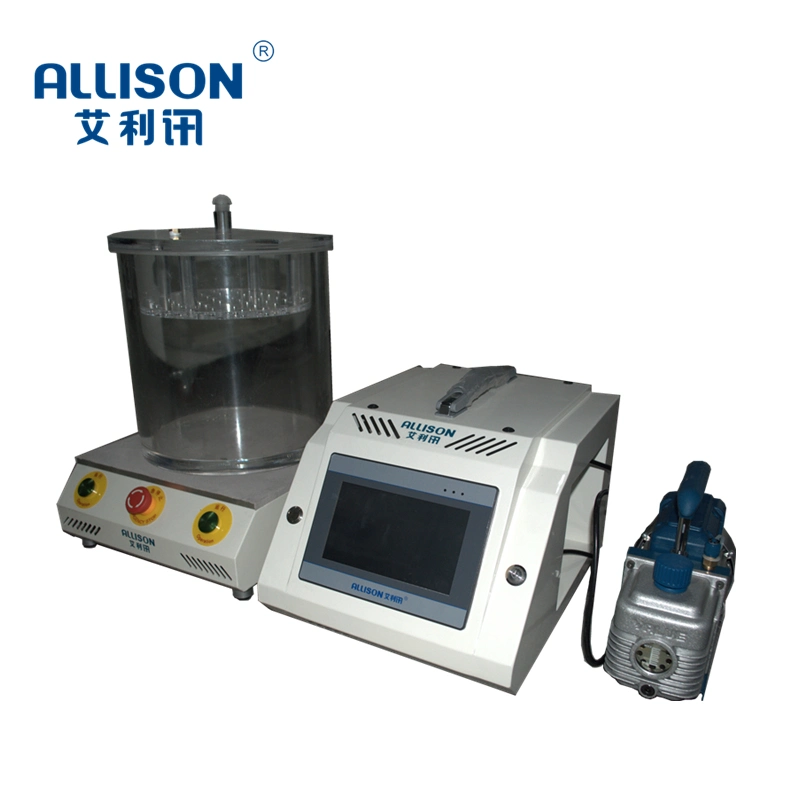

Negative pressure air tightness test machine

Introduction:

Negative pressure type airtightness testing equipment consists of vacuum pump and negative pressure sensor. Through system control, it can quickly perform uninterrupted negative pressure tightness testing of the tested products. Mainly test product tightness and pressure test. The relevant data in the test can be displayed by digital and curve. With data recording function and product data analysis capabilities. The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable. Scope of application: laboratory sealing test and product pressure resistance analysis. Non-standard customization can be made according to customer samples and related requirements.

Technical Characteristics:

1. Number of stations: single station, outlet pipe diameter: 6-10MM (stations can be customized according to customers)

2. Pressure detection mode: negative pressure test mode, negative pressure continuous test mode

3. Control method: PLC Japan Mitsubishi

4. Pressure constant time: 0-99999S arbitrary adjustment

5. Low pressure test pressure: 10~600Kpa arbitrary adjustment

6. Negative pressure test pressure: -100Kpa--0Kpa

7. Test pressure level: 0.1 level

8. Leakage accuracy: 0.1Kpa

9. Use single-phase power supply with ground wire: AC220V±10%, 50Hz 0.75KW

10. Equipment size: 300 X 350 X 280 Unit: MM

---------------------------------------------------------

Introduction:

Negative pressure type airtightness testing equipment consists of vacuum pump and negative pressure sensor. Through system control, it can quickly perform uninterrupted negative pressure tightness testing of the tested products. Mainly test product tightness and pressure test. The relevant data in the test can be displayed by digital and curve. With data recording function and product data analysis capabilities. The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable. Scope of application: laboratory sealing test and product pressure resistance analysis. Non-standard customization can be made according to customer samples and related requirements.

Technical Characteristics:

1. Number of stations: single station, outlet pipe diameter: 6-10MM (stations can be customized according to customers)

2. Pressure detection mode: negative pressure test mode, negative pressure continuous test mode

3. Control method: PLC Japan Mitsubishi

4. Pressure constant time: 0-99999S arbitrary adjustment

5. Low pressure test pressure: 10~600Kpa arbitrary adjustment

6. Negative pressure test pressure: -100Kpa--0Kpa

7. Test pressure level: 0.1 level

8. Leakage accuracy: 0.1Kpa

9. Use single-phase power supply with ground wire: AC220V±10%, 50Hz 0.75KW

10. Equipment size: 300 X 350 X 280 Unit: MM

---------------------------------------------------------